CERN develops manufacturing solutions for machines operating at the limits of precision, size, speed and power.

CERN's Know-How

- High-precision engineering expertise and know-how for micro- and macro-scale components and structures, particularly those operating in harsh environments.

- Unique solutions for the precise and safe handling of large, heavy equipment in confined spaces.

- More than 50 years of civil engineering experience for some of the largest and most complex machines ever built.

Facts & Figures

- >2500 scientific & engineering members of personnel at CERN.

- 0.025 μm: surface roughness (Ra) required for performance of Compact Linear Collider (CLIC) accelerating structures.

- 27 km: circumference of the LHC tunnel – equivalent to the Circle Line in London’s underground system.

- 100 t: weight of each of the “small wheels” lowered 100m into the ATLAS detector cavern with only centimetres of clearance

Value Proposition

Read more about Manufacturing and Mechanical Processes here.

Key Competences

High-precision engineering and assembly at micro & macro scale

CERN components must be built to strict dimensional tolerances and sustain the highest level of performance, especially in challenging environments. Over >50 years, CERN experts have developed specialised procedures and significant experience in precision engineering and assembly, for macro- and micro-scale components.

Thin film coatings for high-performance applications

CERN components must meet demanding expectations in performance and longevity. To achieve this, CERN experts have accumulated over 50 years of experience in the development and application of novel thin film coatings for functional and optical use, including in ultra-high vacuum (UHV) systems and high-energy detectors.

Micro-pattern technologies and processes

CERN personnel develops, prototypes, constructs, maintains and operates some of the largest and most complex detectors in the world. This begins at the micro-scale, with the production of PCBs, thick film and thin film hybrids, flex-rigid boards, fine line flex circuits, large size boards, and sequential build up multilayers with microvias.

Thermal management using silicon microchannels

The volumetric power density of a LHC Pixel detector is approximately 100 W/dm3 - comparable to the most demanding high power electronics applications. To provide stable and precisely controlled thermal management, CERN experts have developed know-how in the design and manufacture of ultra-thin microchannel cooling plates.

Designing stable lightweight carbon fibre structures

Expertise in the design, manufacture, installation and integration of stable, lightweight support structures based on Carbon Fibre Composite Materials, required to provide long lasting structural integrity and stability to the detectors while being exposed to high radiation and magnetic fields.

Heavy equipment handling in complex spaces

Expertise in the design, installation, operation, maintenance and decommissioning of transport and handling equipment – particularly those in confined or difficult-to-access spaces.

Civil Engineering for large-scale infrastructure projects

Civil engineering expertise in the pre-construction and construction phases of large, complex infrastructure – including management of the technical feasibility, geological reality, associated risks and challenges.

Key Applications

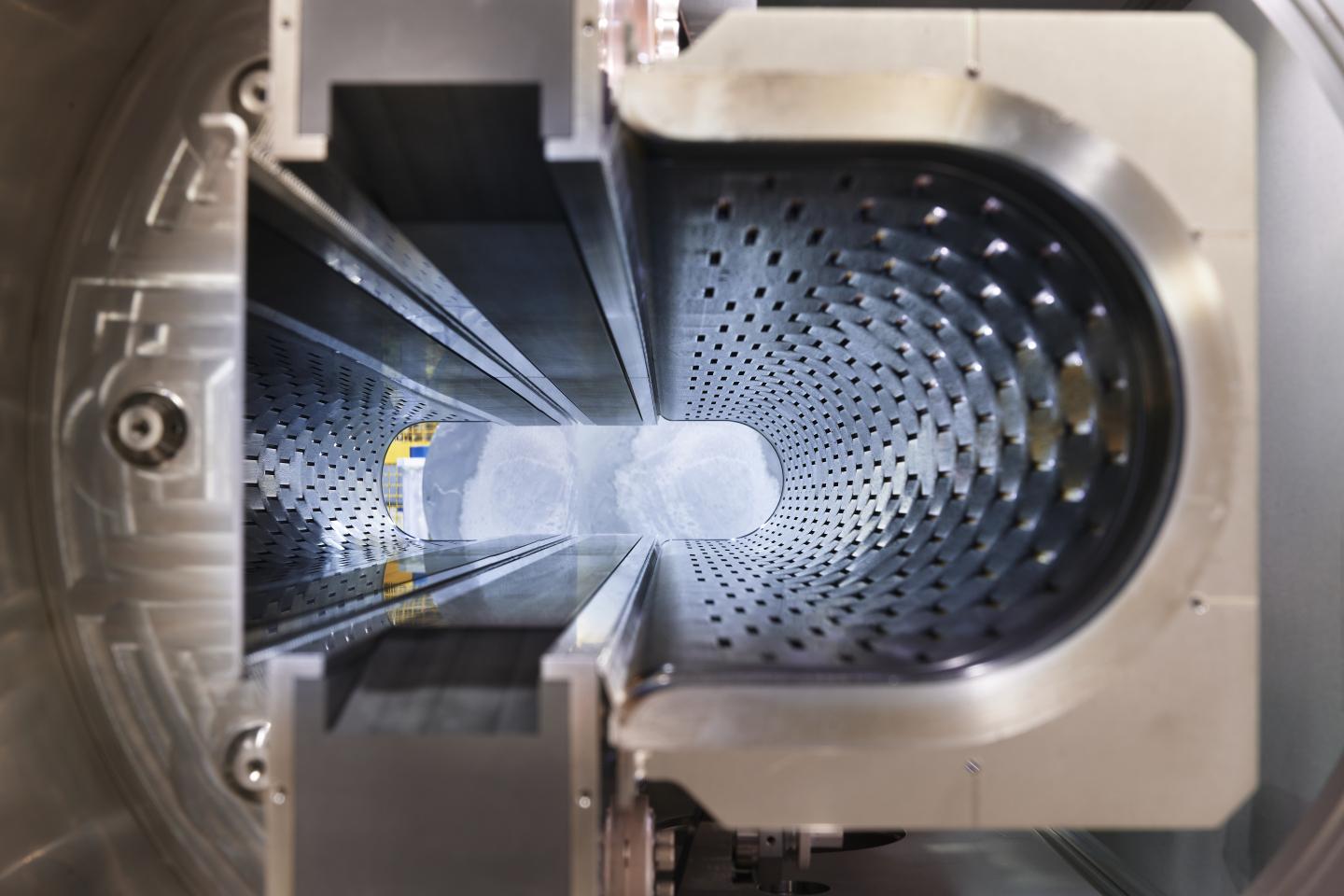

Compact universal pipe cutter

The orbital pipe cutter has been designed to cut a broad range of pipes of different diameters and materials located in places which are particularly difficult to access. Once mounted on a pipe, the cutter operates autonomously without manual assistance.

Rapid bellows compression tool

Where fast, easy and precise installation/removal of metallic bellows is needed, the rapid bellow compression tool is used. It can be adapted to different bellows that vary in shape and diameter, located in poor accessibility areas or requiring controlled compression and precise mounting.